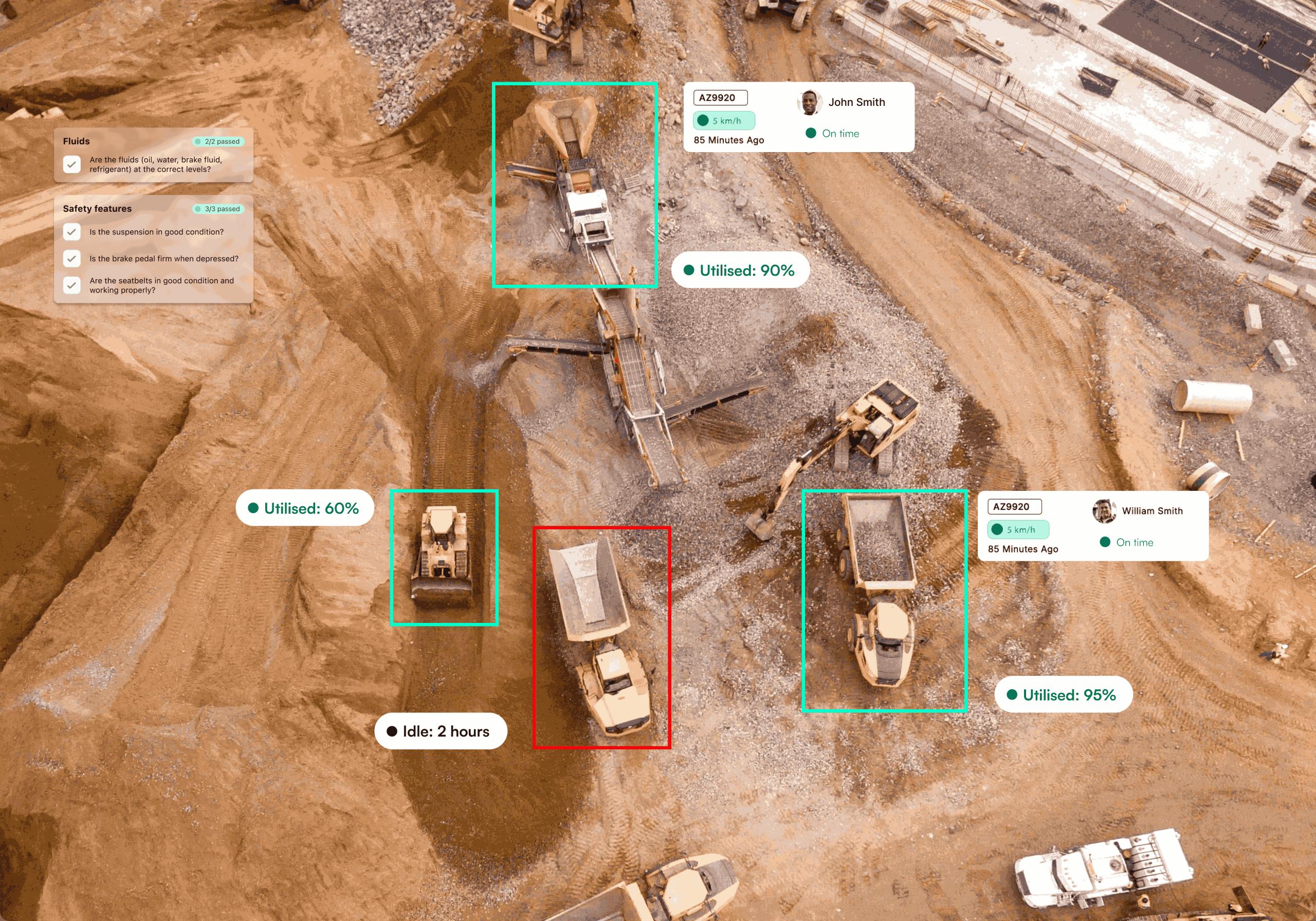

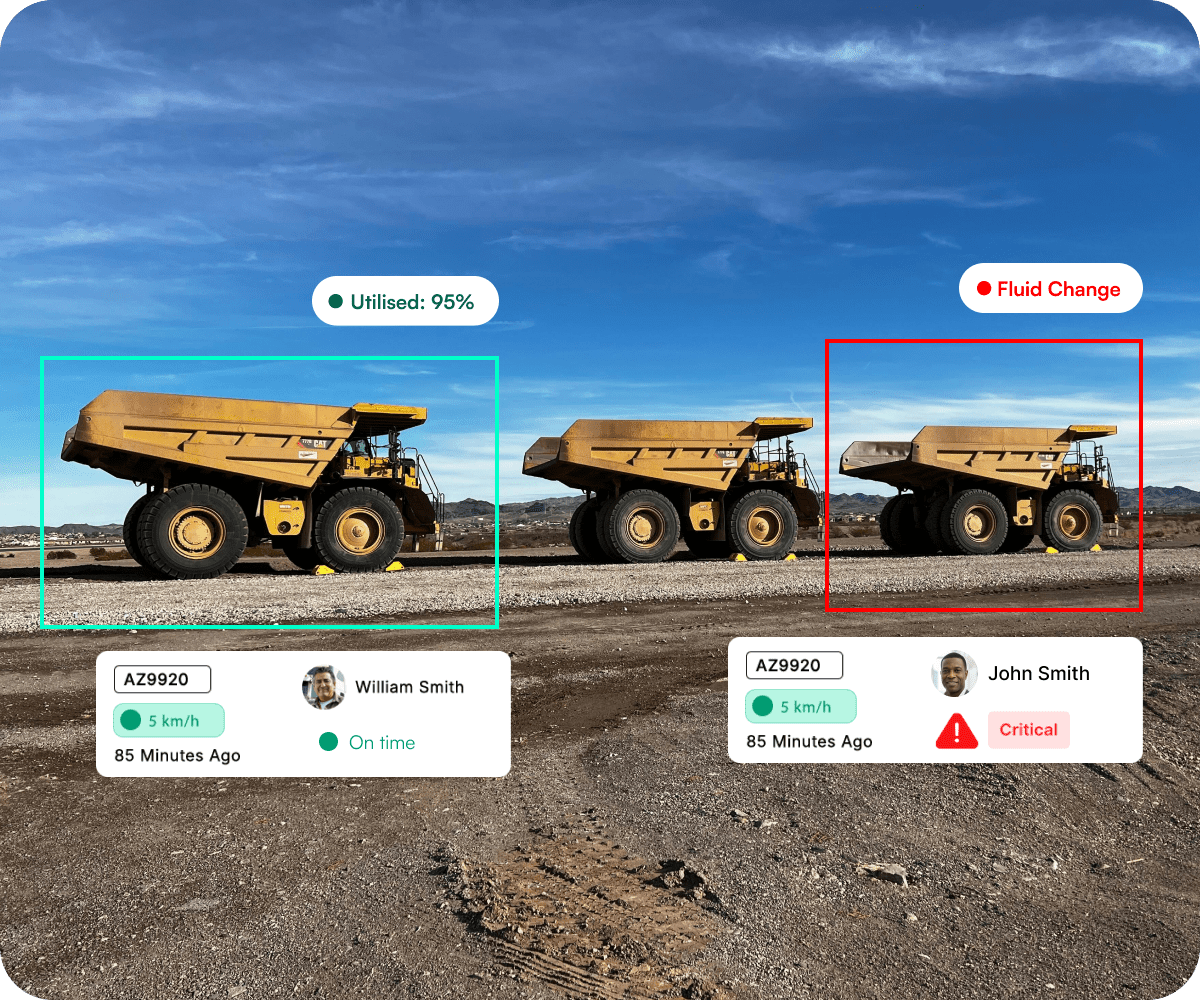

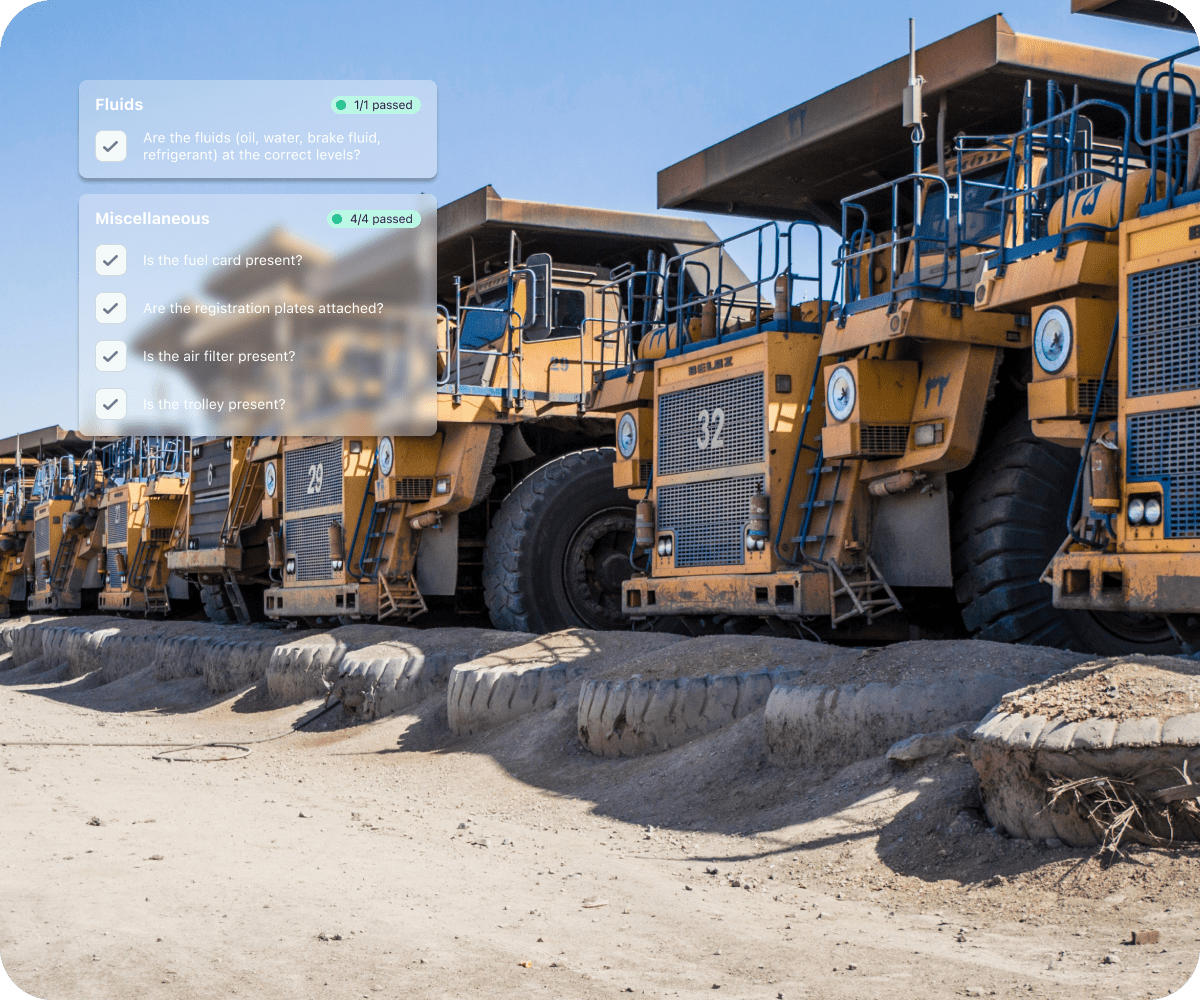

Keep your most valuable equipment performing at its best. Predictive maintenance and real-time tracking deliver early alerts that prevent breakdowns and maximize uptime.

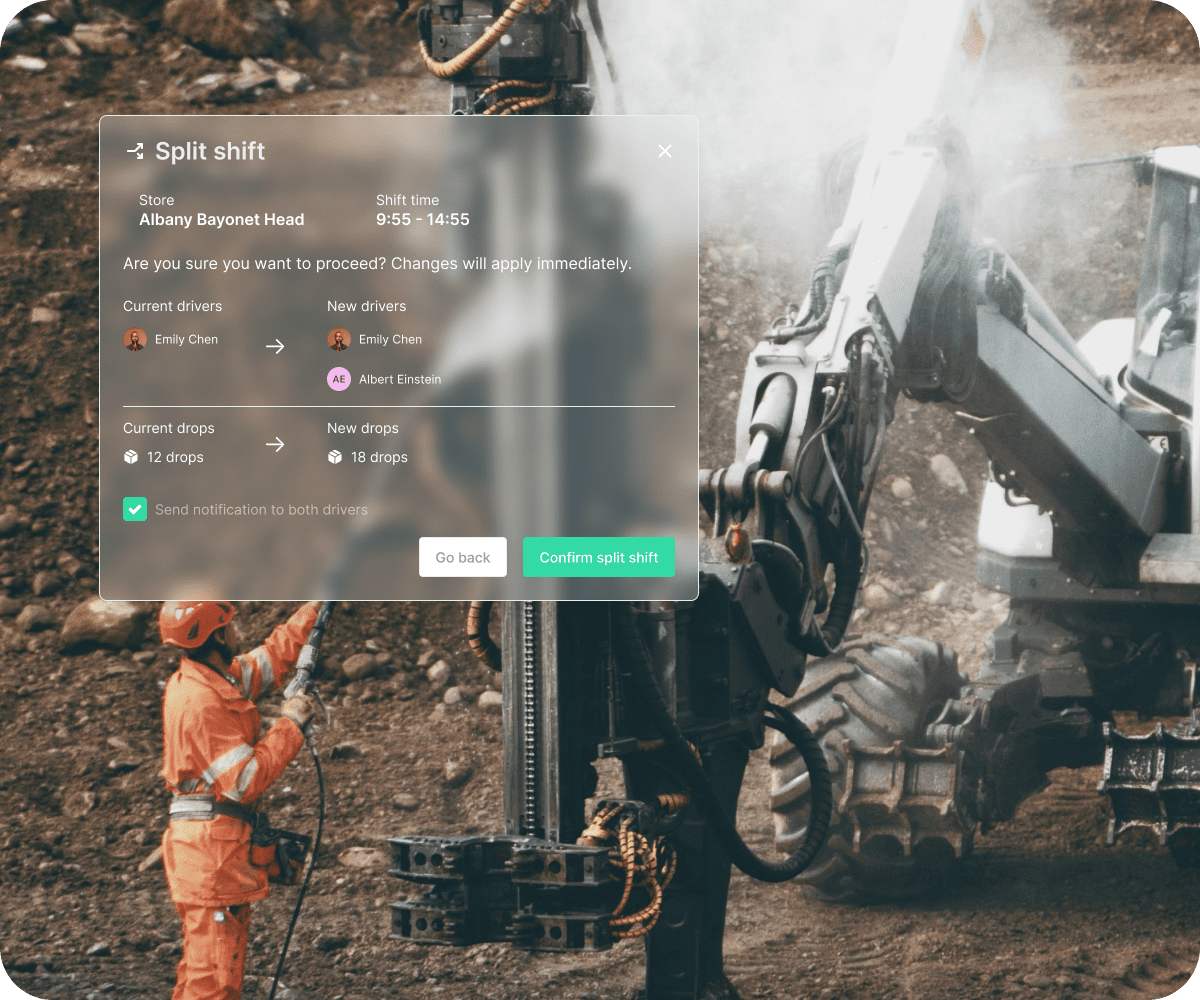

Improve safety compliance with automated monitoring and digital reporting. Verify that every shift, zone access and equipment operation meets required standards.

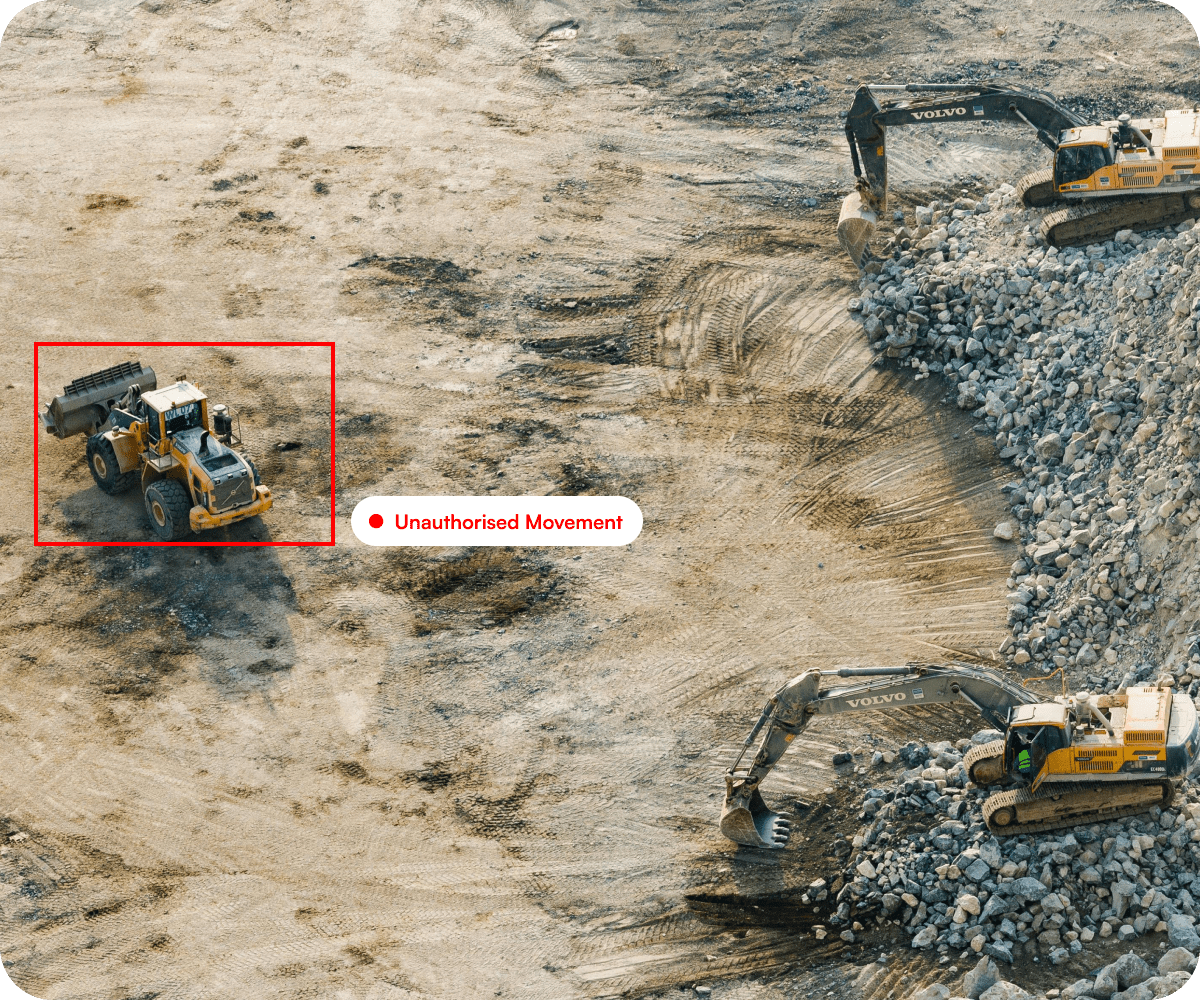

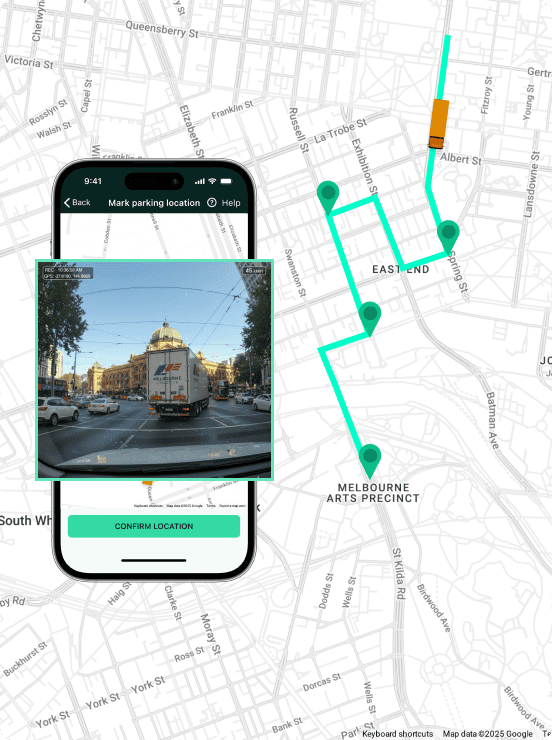

Keep your site secure with smart geofencing and instant alerts. Automatically detect unauthorised access or asset movement and protect your workforce and equipment with real-time notifications.

Managing fuel, equipment use and waste improves efficiency, while optimised routes and reduced idle time lower operational costs.

At Saphyroo, we lead with integrity, innovation and reliability. Our strong ethics and user centric approach have earned the trust of leading companies across the transport industry. We’re driven to help businesses achieve excellence, streamline operations and deliver flawless performance.

Based in Melbourne, Saphyroo combines world class technology and experience with local expertise to create solutions built for Australia’s unique transport conditions. Our products are designed for performance, reliability and compliance boosting safety and efficiency across the industry. Proudly Australian-made, our user-centric technology is intuitive, adaptable and engineered to help businesses meet and exceed national standards.